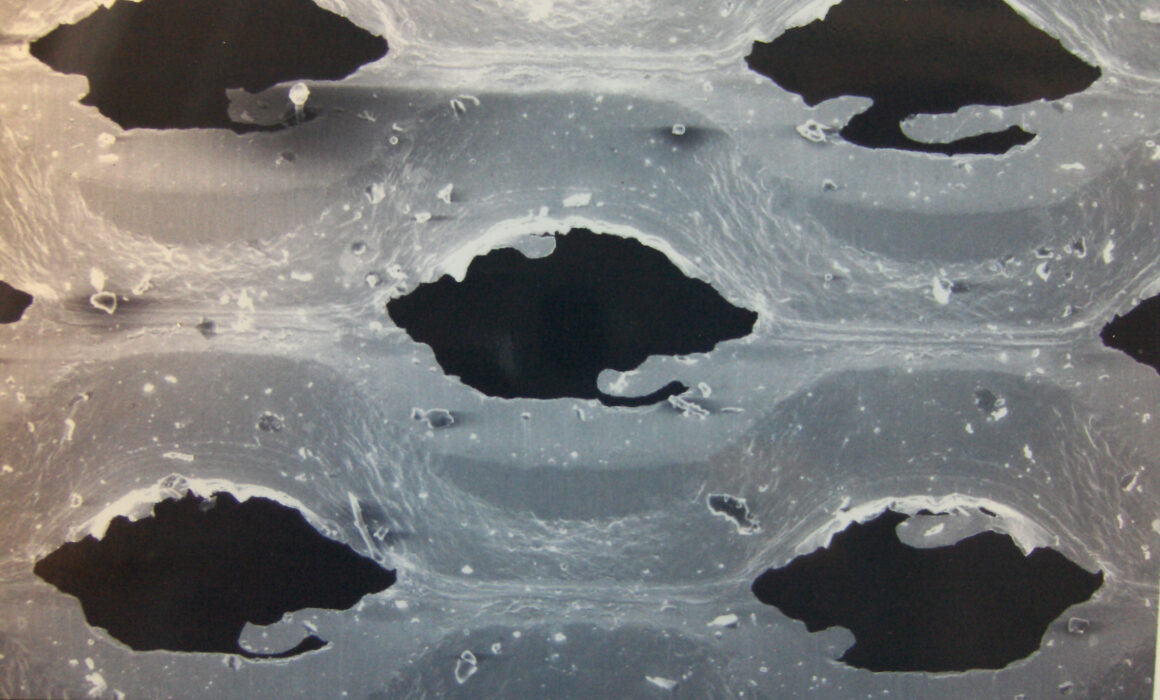

Surface before electropolishing

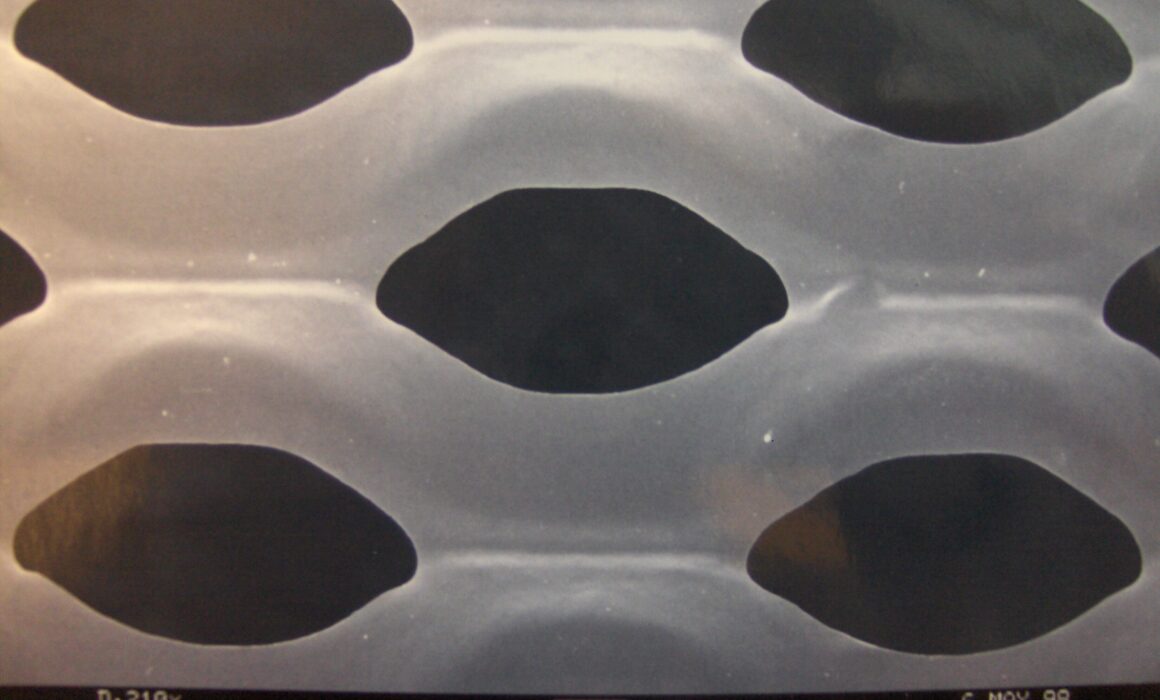

Surface after electropolishing

- 1

- 2

What Is Electropolishing?

Electropolishing is an ablative process that uses specially adapted electrolytes to remove metal anodically. The workpiece forms the anode in an electrochemical cell. Electropolishing reduces the roughness in the micro range, but leaves structures in the macro range. Edges and corners are more strongly reduced, resulting in the finest deburring of the entire surface area. Chrome and chrome-nickel steel are most commonly electropolished. Workpieces treated in this way are much more resistant to corrosion. Electropolishing gives the stainless steel very specific properties. The electropolished surface becomes very beautiful and can be used for all decorative purposes. Especially the shiny metal character is shown to its full advantage.